Technical Support and Services

Service Process

Phase 1: Technical Consultation (1-3 days)

Application condition analysis

Preliminary plan design

Feasibility assessment

Phase 2: Engineering Development (10-15 days)

Detailed design and simulation

Mold solution development

Cost and lead time confirmation

Phase 3: Sample Validation (15-20 days)

Mold manufacturing and trial molding

Sample production and testing

Customer testing and feedback

Phase 4: Mass Production (As per plan)

Raw material procurement

Production and quality control

Packaging and logistics

Phase 5: After-Sales Service

Quality tracking

Technical upgrades

Spare parts support

Frequently Asked Questions

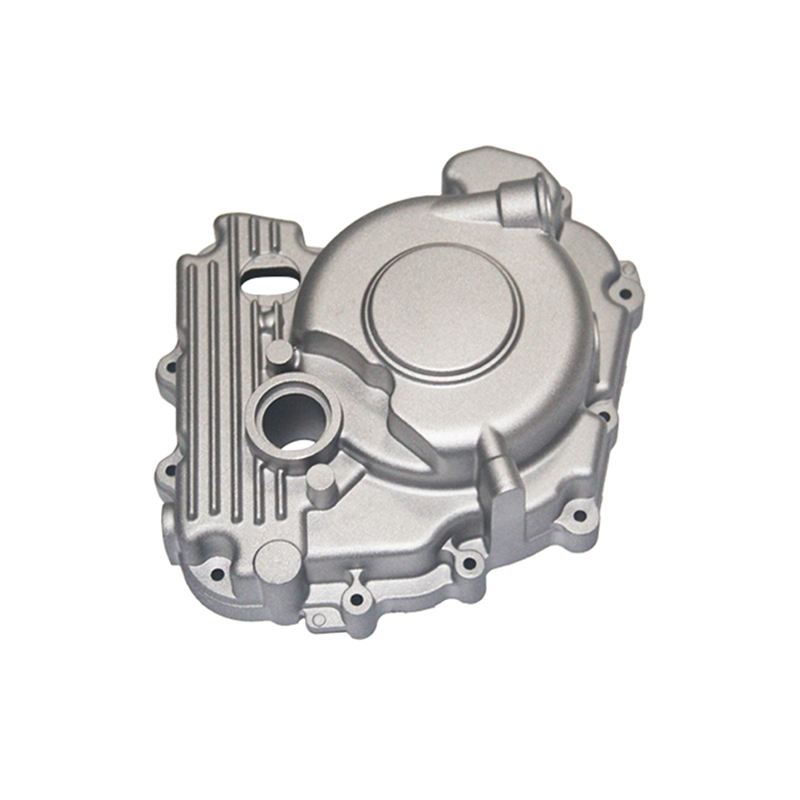

Q: What is the largest size of pump housings you can produce?

A: Currently, the maximum size of pump housings we can produce is 800×600×400mm, with a weight of ≤25kg.

Q: What is the highest pressure rating achievable?

A: The standard products can handle up to 35MPa, and special designs can reach up to 50MPa.

Q: Is there a minimum order quantity (MOQ)?

A: There is no MOQ during the sample stage. For mass production, the MOQ is generally 50-100 pieces depending on the complexity of the product.

Q: What are the available surface treatment options?

A: The available surface treatments include anodizing (in various colors), chemical nickel plating, Teflon coating, powder coating, etc.

Q: Do you offer internal machining services?

A: Yes, we provide complete machining services, including turning, milling, drilling, honing, and more.

Q: What is the lifespan of the molds?

A: The lifespan of pump housing molds is ≥80,000 cycles, while valve body molds last ≥100,000 cycles.

Sample Request and Quotation

We believe seeing is believing, and we offer free sample services:

Sample Application Process:

1. Provide drawings or technical requirements

2. Technical evaluation and solution confirmation

3. Sample production and testing

4. Sample delivery and feedback

5. Discussion for mass production cooperation

Quick Quotation Channel:

Submit basic information online and receive a preliminary quotation within 24 hours

Provide a detailed quotation after technical communication

Offer cost optimization proposals

English

English Español

Español русский

русский