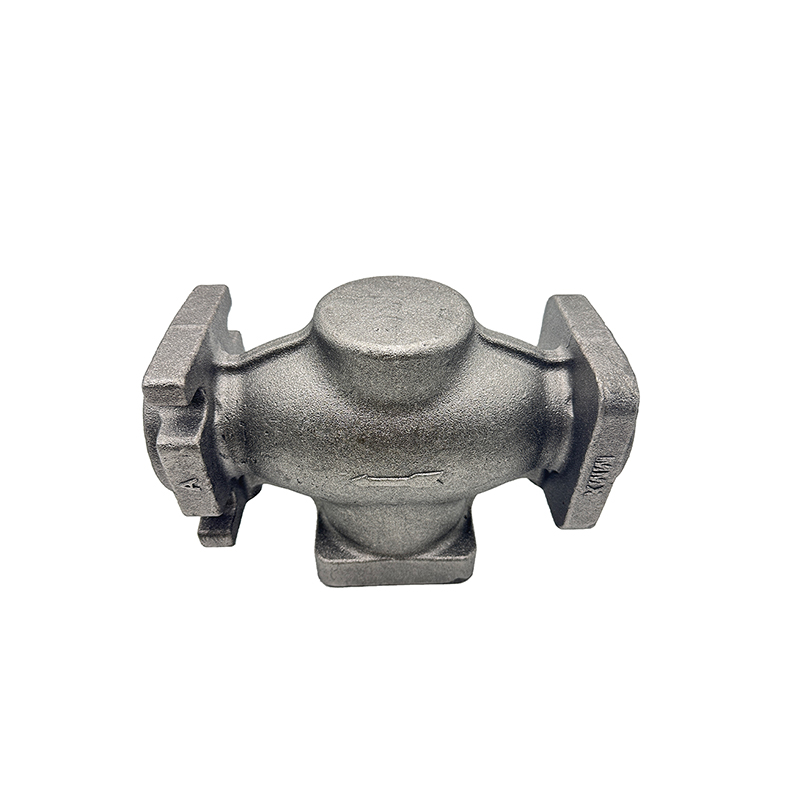

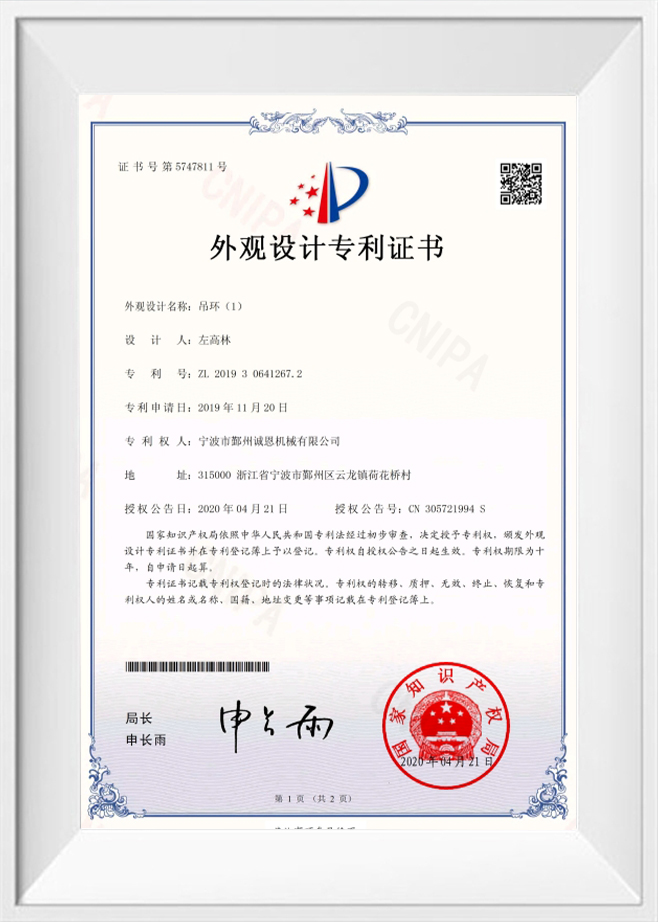

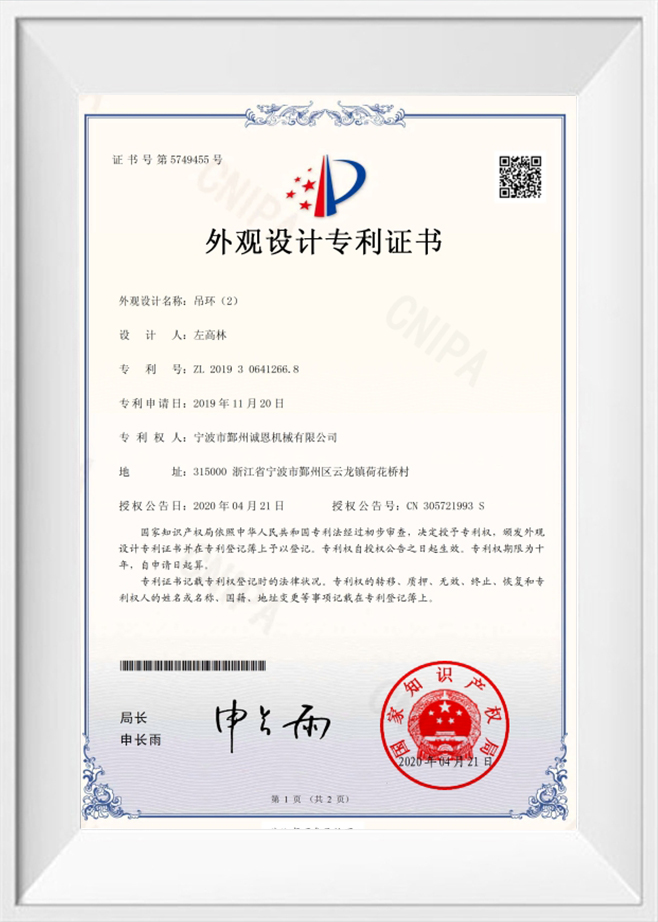

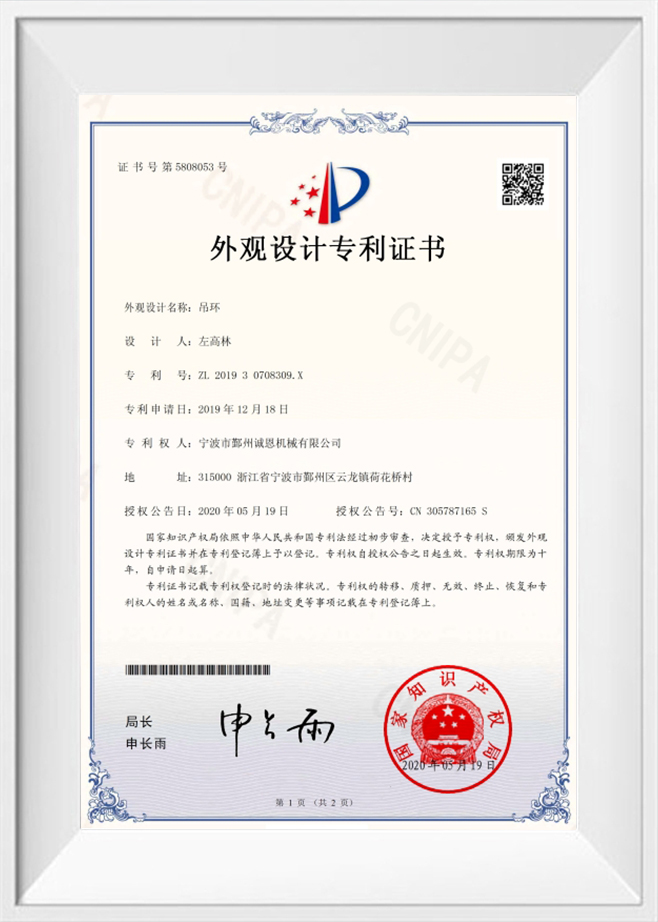

Ningbo Chengen Machinery Co., Ltd. was established in 2008. It is a professional manufacturing enterprise integrating casting and machining, committed to providing customers with high-quality one-stop solutions. The company is located in Jiangshan Town, Yinzhou District, Ningbo City. It has a modern production base of 12,000 square meters, equipped with advanced production equipment and a professional technical team. It has won wide recognition in the market with its excellent manufacturing capabilities and rigorous quality control.

Introduction to Aluminum Die Casting The trajectory of modern industrial design has been defined by ...

READ MORE English

English Español

Español русский

русский