About Hot Forged Parts

The Hot Forged Parts Industry is a cornerstone of modern manufacturing, as it enables the creation of high-strength components that are essential in industries that demand both performance and durability. Hot forging involves heating metal to above its recrystallization temperature, then applying pressure to shape it into the desired form. This process significantly enhances the mechanical properties of the metal, such as strength, toughness, and wear resistance, making it an ideal method for manufacturing parts that will endure high temperatures, stress, and friction. The parts produced are used in a wide range of critical applications, from automotive engine components to aerospace turbine blades.

Hot forging offers superior benefits, including greater resistance to fatigue, improved toughness, and more uniform grain structure, which translates to more reliable performance in high-demand environments. The Hot Forged Parts industry is indispensable in the automotive sector, where components like crankshafts, axles, and gearboxes require not only strength but also precise tolerances to ensure smooth functioning. In the industrial equipment and heavy machinery sectors, Hot Forged Parts are crucial for producing components such as gears, shafts, and hydraulic valves that can withstand mechanical stress and high temperatures. The aerospace industry also relies heavily on hot forging for parts like turbine blades and structural components that must endure extreme operating conditions while maintaining structural integrity.

| Industry |

Applications |

Examples of Parts |

| Automotive |

Engine components, suspension systems, crankshafts |

Crankshafts, connecting rods, suspension arms |

| Aerospace |

Turbine blades, landing gear, engine components |

Turbine blades, engine housings, landing gear |

| Industrial Equipment |

Gears, shafts, hydraulic systems |

Gears, shafts, hydraulic valves |

| Heavy Machinery |

Gears, valves, pumps |

Pump housings, gears, valves |

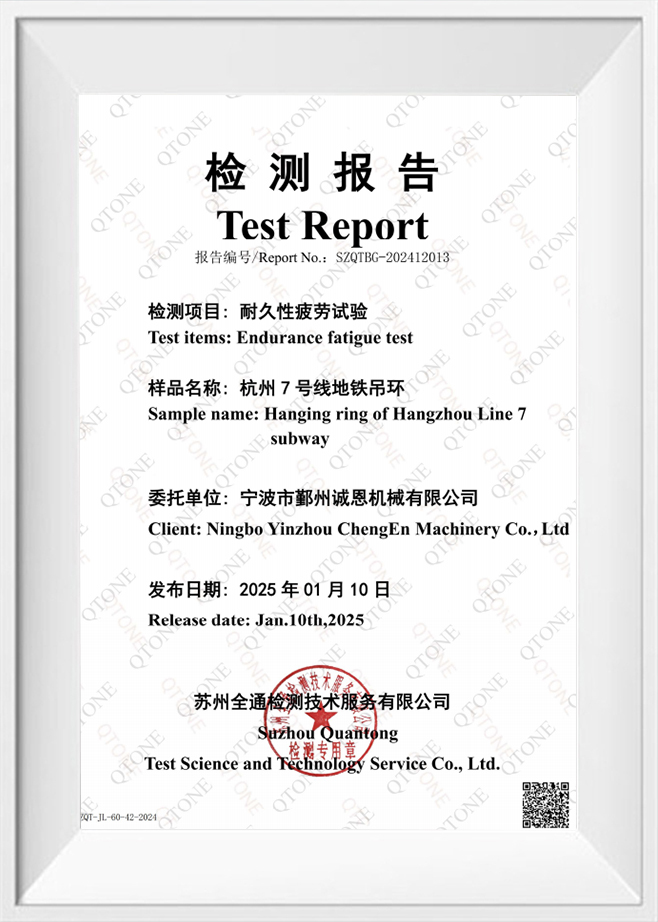

As the demand for precision and performance continues to grow, NingBo YinZhou ChengEn Machinery Co., Ltd., established in 2008, has positioned itself as a leading Hot Forged Parts manufacturer. The company’s modern production facility, located in Jiangshan Town, Yinzhou District, Ningbo City, covers 12,000 square meters and is equipped with state-of-the-art production machinery. This enables the company to produce high-performance Hot Forged Parts that meet the most stringent industry standards. The company offers both Wholesale Hot Forged Parts and custom forging solutions, providing industries worldwide with parts designed to meet specific performance and durability requirements. NingBo YinZhou ChengEn Machinery Co., Ltd. is known for its rigorous quality control, ensuring that all products are manufactured with the utmost precision and reliability.

This combination of advanced equipment, skilled workforce, and a commitment to quality makes NingBo YinZhou ChengEn Machinery Co., Ltd. a trusted partner for industries seeking high-quality Hot Forged Parts. Whether for large-scale production or custom orders, the company’s capacity to deliver parts that meet the complex demands of sectors like automotive, aerospace, industrial machinery, and heavy equipment sets it apart as a key player in the global Hot Forged Parts market.

The Role of Hot Forged Parts in Key Industries

In the automotive industry, Hot Forged Parts are critical for producing components such as engine blocks, crankshafts, and suspension parts. These parts must be designed to endure extreme conditions, including high temperatures, mechanical stress, and vibrations. Hot forging offers significant benefits in this context, as it enhances the strength and durability of these components, making them ideal for demanding automotive applications. The high-performance characteristics of Hot Forged Parts contribute to improved vehicle performance, better safety features, and extended service life, ultimately enhancing the overall longevity of the vehicle.

For industrial equipment and heavy machinery, Hot Forged Parts are used to manufacture essential components like gears, shafts, hydraulic systems, and pump parts. These parts are subjected to high pressure, mechanical stress, and abrasive wear in environments that demand reliability and resilience. The precision and strength achieved through the hot forging process ensure that these components can perform consistently and reliably, even under extreme industrial conditions. Hot Forged Parts manufacturers play a key role in producing these critical components, offering both Wholesale Hot Forged Parts and custom solutions for industries requiring durable, high-performance parts.

In the aerospace industry, Hot Forged Parts are used to create high-stress components like turbine blades, landing gear, and structural elements that must endure not only high pressure but also significant thermal stress and corrosion. The ability to achieve a high strength-to-weight ratio and precise tolerances through hot forging is essential for ensuring the safety, performance, and efficiency of both aircraft and spacecraft. These parts must meet stringent quality standards, and the reliability of Hot Forged Parts suppliers ensures that aerospace manufacturers can trust in the parts they source for critical applications.

As industries in China and around the world continue to demand high-quality, high-performance components, the expertise and innovation of Hot Forged Parts manufacturers are crucial for meeting these needs. By providing Wholesale Hot Forged Parts and custom forging solutions, these suppliers enable industries such as automotive, aerospace, and heavy machinery to maintain their competitive edge while ensuring the safety, efficiency, and durability of their products.

Key Advantages of Hot Forged Parts

Strength and Durability

Hot forging is a transformative manufacturing process that significantly enhances the mechanical properties of metals, making it an essential technique in industries that demand high-strength, durable components. In hot forging, metal is heated above its recrystallization temperature and then shaped under high pressure. This process not only allows the material to be formed into complex shapes but also results in a more homogeneous microstructure, which is crucial for improving the overall mechanical properties of the metal.

| Advantage |

Description |

| Strength and Durability |

Hot forging enhances the mechanical properties of metals, increasing their resistance to wear and fatigue. |

| High Precision |

Hot forging allows the creation of parts with tight tolerances and intricate geometries, critical for aerospace and automotive sectors. |

| Efficiency |

Reduces the need for additional machining or finishing, making it a time-efficient process. |

| Versatility |

Hot forging can work with various metals like steel, titanium, and aluminum, suitable for multiple industries. |

By heating the metal to a high temperature, hot forging ensures that the material becomes more ductile and easier to shape. As the material is compressed and deformed under pressure, it undergoes a refinement in its grain structure, which leads to improved strength, toughness, and resistance to wear and fatigue. These enhanced properties make Hot Forged Parts particularly well-suited for applications in industries such as automotive, aerospace, and heavy machinery, where components are subjected to extreme conditions and need to perform reliably over long periods.

One of the key benefits of hot forging is its ability to improve the resistance to wear. Components like engine parts, crankshafts, and gears, which experience high friction and pressure, require exceptional wear resistance to ensure long-lasting performance. The refining process during hot forging allows the material to resist abrasion and other forms of wear that could otherwise compromise the part’s functionality and lifespan. This enhanced wear resistance is especially valuable in the automotive industry, where parts are exposed to continuous friction, as well as in heavy machinery applications, where parts are subjected to harsh environments and heavy loads.

Additionally, fatigue resistance is another critical benefit of hot forging. When components experience repeated loading and unloading cycles, they can develop cracks or fail due to material fatigue. Hot forging improves the metal's ability to withstand these stresses, ensuring that parts like turbine blades, suspension components, and structural elements maintain their integrity even after prolonged use. This is particularly important in industries such as aerospace, where components are exposed to repeated stress during operation and need to perform reliably over time.

In industries where reliability and durability are paramount, hot forged parts provide an unparalleled combination of strength and endurance. The process not only ensures that parts can withstand extreme temperatures and mechanical stress but also guarantees that they will perform optimally throughout their lifespan. This is especially crucial in critical systems, where failure is not an option, and the performance of each component directly impacts the safety and functionality of the entire system.

Ultimately, hot forging is an indispensable process that offers significant improvements to the mechanical properties of metals. By enhancing strength, wear resistance, and fatigue resistance, it ensures the longevity and reliability of components in demanding industries. Whether it's ensuring the performance of a vehicle's engine, the safety of an aircraft's structural elements, or the efficiency of industrial machinery, hot forged parts deliver the durability needed to meet the most challenging applications.

High Precision

A key advantage of hot forging is its exceptional precision, a critical factor in industries where the accuracy of components is paramount. The controlled conditions under which hot forging takes place, including high temperatures and precise pressure application, allow for the creation of parts with intricate geometries and tight tolerances. This level of precision is especially important in sectors such as aerospace, automotive, and heavy machinery, where even the slightest deviation in a part’s dimensions can result in serious malfunctions or failures.

Hot forging ensures that parts are produced with highly detailed internal features and complex geometries that would be difficult, if not impossible, to achieve through other manufacturing processes. Components such as engine parts, turbine blades, and structural elements in aircraft are prime examples of parts that benefit from the precision of hot forging. These parts often require internal cooling channels, lightweight structures, or high-strength attributes, all of which are achievable with the precision provided by hot forging.

In the aerospace industry, for example, turbine blades must be able to withstand extreme temperatures and pressure while maintaining structural integrity. The high precision of hot forging ensures that these blades fit perfectly within turbine assemblies, improving performance and safety. Similarly, in the automotive industry, engine blocks and crankshafts must meet precise specifications to function optimally under high stress and temperature conditions. Hot forging provides the accuracy needed to meet these critical requirements.

The precision of hot forging also improves the overall functionality and reliability of the end product. Each part fits seamlessly into the broader system, which is essential for maintaining the integrity of complex machines and systems. Whether it’s ensuring the reliability of a jet engine or the performance of an automotive drivetrain, the high precision of hot forged parts guarantees that every component meets exacting standards and performs as intended.

In conclusion, hot forging stands out as a process that offers unparalleled precision, making it an ideal choice for industries that rely on highly detailed and accurate components. The ability to achieve tight tolerances and intricate geometries ensures that hot forged parts not only fit into their designs perfectly but also perform reliably under the most demanding conditions.

Efficiency

Hot forging stands out as an exceptionally efficient method for producing components that are not only strong but also highly precise. This efficiency stems from the fact that the hot forging process significantly reduces the need for additional machining or finishing steps. The process itself is designed to create parts with tight tolerances and intricate geometries right out of the forge, which means fewer adjustments are needed afterward. This reduction in post-processing requirements directly translates to notable time and cost savings for manufacturers.

By eliminating the need for extensive machining or surface treatments, hot forging makes it possible to produce high-quality parts in less time. This is particularly beneficial for large-scale production runs where speed and cost-effectiveness are essential. For example, in industries like automotive, aerospace, and heavy machinery, manufacturers can achieve faster turnaround times without sacrificing quality. As a result, hot forged parts can be produced more quickly, ensuring a faster time-to-market for products that rely on these critical components.

Moreover, the efficiency of hot forging helps companies optimize labor costs. Since fewer workers are required for finishing operations, manufacturers can reduce their labor expenses while increasing the output of high-precision parts. This combination of reduced post-processing, lower labor costs, and faster production times makes hot forging an attractive option for companies that need to maintain competitive pricing while delivering reliable, durable parts.

In summary, the efficiency of hot forging not only enables manufacturers to produce top-quality components but also provides the added benefits of cost reduction and increased production speed. This makes it a highly attractive solution for industries looking to streamline operations while ensuring the durability and strength of the parts they produce.

Versatility

Another significant benefit of hot forging is its versatility in terms of the materials it can accommodate. Whether it's steel, aluminum, titanium, or superalloys, hot forging can work with a wide variety of metals to create components for a range of applications. This flexibility makes it a go-to solution for Hot Forged Parts manufacturers who need to create components for industries as diverse as automotive, aerospace, construction machinery, and industrial equipment. The ability to forge different types of metals enables manufacturers to tailor the properties of the end product to meet the specific requirements of each industry, whether it's enhancing strength, corrosion resistance, or thermal stability. As a result, hot forging remains a highly adaptable and valuable manufacturing process across multiple sectors.

Why Choose NingBo YinZhou ChengEn Machinery Co., Ltd. for Hot Forged Parts

NingBo YinZhou ChengEn Machinery Co., Ltd. is a trusted name among Hot Forged Parts suppliers in China, known for its years of expertise in the hot forging industry. Established with a strong commitment to quality and precision, the company specializes in providing high-performance Hot Forged Parts for a variety of industries, including automotive, aerospace, heavy machinery, and industrial equipment.

With a state-of-the-art production facility and an experienced technical team, NingBo YinZhou ChengEn Machinery Co., Ltd. offers a broad range of hot forging solutions tailored to meet the specific requirements of each client. Whether you're looking for Wholesale Hot Forged Parts for mass production or need custom solutions for specialized applications, the company guarantees reliable, durable, and cost-effective parts that meet international quality standards. Their ability to adapt to changing market needs and provide personalized services has made them a preferred choice for companies worldwide seeking top-tier forged components.

FAQ

What is Hot Forged Parts?

Hot Forged Parts are components created through the hot forging process, where metal is heated above its recrystallization temperature and then shaped under high pressure. This process enhances the material properties of the metal, improving its strength, durability, and resistance to wear and fatigue. The Hot Forged Parts are ideal for industries that require high-performance components capable of withstanding extreme conditions. The hot forging process is used to produce complex parts with precise geometries and tight tolerances, making them suitable for industries like automotive, aerospace, industrial equipment, and heavy machinery. The ability to produce robust and reliable components is why hot forging is widely preferred in these sectors.

Why is Hot Forging used in the automotive industry?

| Material |

Characteristics |

Common Uses |

| Steel |

High strength, widely used, versatile |

Automotive, industrial equipment |

| Titanium |

Lightweight, corrosion-resistant |

Aerospace, automotive |

| Aluminum |

Lightweight, cost-effective |

Automotive, industrial machinery |

| Superalloys |

High-temperature resistance, durable |

Aerospace, heavy machinery |

Hot forging is particularly well-suited for automotive applications due to its ability to produce parts that can endure extreme mechanical stress, high temperatures, and continuous vibrations. Automotive components such as engine blocks, crankshafts, connecting rods, and suspension parts require enhanced strength and resistance to wear. Hot forged parts are able to maintain structural integrity under these demanding conditions, which is essential for ensuring the long-term performance and safety of vehicles. Hot forging also offers the advantage of producing components that are resistant to fatigue and can handle high-pressure environments. The combination of precision, strength, and durability makes hot forged parts ideal for critical automotive applications where failure is not an option.

What are the key benefits of Hot Forged Parts?

The key benefits of Hot Forged Parts are numerous and include the following:

High strength: Hot forging enhances the inherent strength of metals by aligning the grain structure of the material. This provides parts that can handle high mechanical stress and extreme operating conditions without compromising their integrity.

Durability: Hot forged parts are designed to withstand prolonged wear and tear, making them ideal for industries like automotive, aerospace, and heavy machinery where components are subjected to continuous stress, high temperatures, and vibration. The enhanced mechanical properties result in longer-lasting parts that require less maintenance and fewer replacements.

Resistance to wear and fatigue: The hot forging process makes parts highly resistant to wear and fatigue. Components such as gears, crankshafts, and suspension parts produced by hot forging are more capable of enduring the friction, pressure, and repetitive cycles they experience in demanding applications.

Precision: Hot forging allows for the creation of parts with high precision, tight tolerances, and intricate geometries. The process minimizes the need for additional machining or finishing, as the components come out of the forge with near-perfect dimensions. This is especially important in industries like aerospace, where precision and reliability are paramount.

Long service life: Due to the enhanced strength and durability, hot forged parts often enjoy a significantly longer service life than parts made using other manufacturing methods. Their resistance to mechanical stress, high temperatures, and corrosion reduces the need for frequent replacements, making them a cost-effective choice for industries with high-volume production needs.

Efficiency: Hot forging eliminates the need for extensive post-processing, making it a highly efficient manufacturing process. Since the parts come out of the forge with minimal finishing required, manufacturers can reduce production time and costs, especially for large-scale production runs.

Can Hot Forged Parts be customized?

Yes, Hot Forged Parts can be fully customized to meet the specific requirements of each industry and customer. Manufacturers can adjust the forging process to produce components with tailored dimensions, material properties, and shapes, ensuring that each part meets the unique needs of the application. Whether it's for small batch production or large-scale manufacturing, Hot Forged Parts manufacturers have the flexibility to create parts that conform to the highest industry standards. This makes it possible to produce custom solutions for industries such as aerospace, automotive, and heavy machinery. Additionally, the ability to modify the material properties during the forging process allows manufacturers to create parts with specific performance characteristics, such as enhanced wear resistance, heat tolerance, or strength.

English

English Español

Español русский

русский